ReadyLIFT Forged Torsion Keys – How They Work & Why They are Better

First, a history lesson. Torsion bar suspensions have been around since the early 1900s where they first made their debut on some passenger cars. Over the decades that followed many manufacturers adopted a torsion bar suspension design for some of their platform offerings. In 1960 GM was one of the first to put a torsion bar suspension under a light duty truck. This design was short lived and ended in 1963. The revival of torsion bar suspensions under pickup trucks began more than a decade later when independent front suspensions became popular due in part to their improved overall performance and ride characteristics compared to the leaf-sprung counterpart.

How does your torsion bar suspension work? Torsion bars work just like the name implies. Its function is to use torsion (twisting resistance) force in the same way a coil spring works. Using the GM truck application as an example, one end of the torsion bar remains stationary mounted to the frame cross member. The opposite end inserts into the lower control arm. In between is a location for the lever – the torsion key – which basically holds the torsion bar at the preferred height required for how the vehicle is supposed to sit. As the wheel cycles up or down, the torsion bar twists around its axis. As it does so, the resistance increases as the bar wants to return its axis of zero resistance.

“What happens when I crank up my stock keys?” Several things happen. The most noticeable is the key tops out inside of the top of the torsion key cross member. What this does is prevents the torsion bar from rotating any further. If you crank up your torsion key to the point that it tops out or near tops out, you will have zero down travel (rebound) past the adjusted static height point. This is one of the most obvious issues that contribute to a poor ride quality when cranking up your stock keys. Additionally, without the aid of shock extensions or longer shocks, your shocks will “bottom out” at droop and most assuredly destroy your shocks

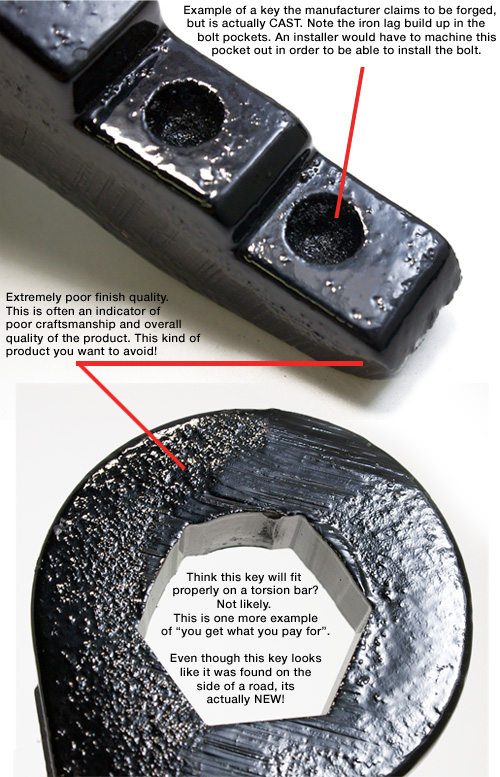

Over a decade ago, ReadyLIFT was the first company to offer a Forged torsion key that would allow the customer to raise the front suspension of their torsion bar equipped truck by incorporating a unique method of “re-indexing” or “re-clocking” the key. We designed our keys to mimic the factory keys in shape and function but changed – in degrees – the hexagon hole in the key enough to where it can provide a maximum of 2.5 inches of torsion lift with the torsion key remaining in the stock position inside of the cross member. The hexagon hole in the lever key fits snug to the location on the torsion bar where it is designed to slide onto and hold snug to the bar with no gaps or “slop”. This is the point where the torsion key applies adjustable force to the torsion bar and ultimately rotates the torsion bar and providing “lift”.

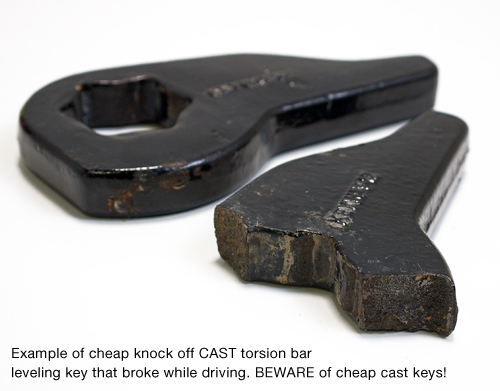

Our engineers discovered the perfect re-clocking sweet spot that, when properly installed and adjusted per our instructions, will provide the user with the right amount of front lift to level the truck without compromising the ride quality. Most of our forged torsion keys come with shocks extensions so you can remain confident that your stock shocks will work just fine. We protect our keys with a strong E-coat finish that will not rust like the bare cast factory keys or cheap cast imitations. Genuine ReadyLIFT Forged Torsion Keys are 25% stronger than the factory key, include extra large adjusting bolt and tool hole pockets for easy installation, and our hexagon index holes are specifically designed to grab the flat of the bar resulting in no key slop which is common on cheap imitation keys. With a lifetime guarantee, ReadyLIFT forged torsion keys are guaranteed not to break or fail. (see attached images of broken cheap “leveling” keys).

Translate

Translate